Hg special dryer for ginkgo leaves

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

In order to develop the abundant ginkgo leaf resources in China, our factory has designed and manufactured Hg series ginkgo leaf drying equipment according to the characteristics of the fresh ginkgo leaf, which has laid a good foundation for the deep processing of the ginkgo leaf, completely solved the problems of perishable, difficult transportation and storage of the fresh ginkgo leaf, and ensured the high-efficiency composition, color, fragrance and taste of the ginkgo leaf. And it has been successfully applied all over the country. Through the use of users, the production unit is an ideal drying equipment for ginkgo leaves and Forages in China.

Dhzg series three return rotary drum dryer is the first generation of China's multi return drum dryer designed and manufactured by our factory in 1992 by absorbing the advanced technology of Surveying and mapping abroad. It is suitable for large-scale continuous production of small size, high moisture content and loose light materials. It can be equipped with coal, biomass particles, wood blocks, oil, gas, direct and indirect hot air stoves, with high degree of automation and good quality of drying products. The drying system is equipped with safety and fire protection devices, hot air waste heat utilization and other devices, with low cost and safe and reliable production.

The equipment is composed of three inner and outer sleeves. When the inner cylinder of two layers is dry, the inner and outer materials can be heated to effectively utilize the heat. The materials are added from the inner cylinder and discharged through the second layer to the outer layer. The actual drying length is three times of the external length of the equipment, effectively extending the drying time, so that the materials can be fully dried. The dried materials enter into the discharge system along with the air flow, and the mixed sundries, iron nails, bricks, etc. can enter into the deposition device for regular discharge. The materials are discharged by the cyclone separator through the air blower. If the environmental protection requirements are strict, the bag dust remover can be added after the cyclone. It is widely applicable to sawdust, shaving, sawdust, straw, leaves, bark, marigold, alfalfa, gingko leaf, distiller's grains, and middle grass. The heat efficiency of drying materials such as medicine, malt, sugarcane leaves and hawthorn leaves is up to 80%, which is significantly higher than that of similar domestic equipment. Three sets of drum dryers adopt the new technology of high temperature and fast drying, three return structure, small floor area, special board reading, high heat transfer coefficient, high efficiency, fast drying speed, high drying intensity, short residence time, automatic temperature control, to ensure the quality of dried products, simple and safe production operation and reliability.

Hg series drum dryer has obtained CE certification in August 2012: no.od121026/cn21575

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

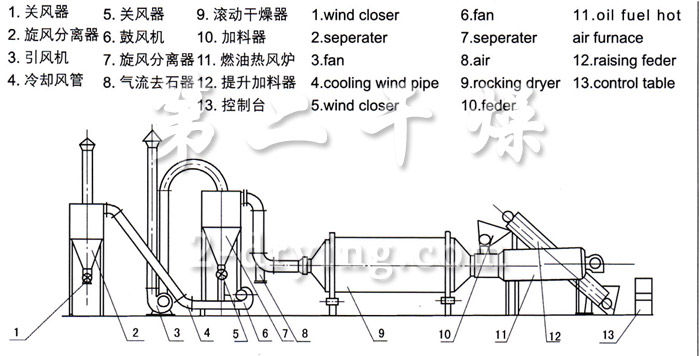

The high-temperature flue gas is used as the medium to enter the drum dryer. The downstream drying process is adopted. Four small rollers are set at the lower part of the drum to support and drive the drum dryer to rotate. The fresh leaves are transported to the feeding port by the lifting feeder for adding. The wet material is brought into the rotary dryer room by hot air. Under the action of the plate and air flow in the cylinder, the material moves forward continuously, so that the wet material fully contacts with the hot air to generate heat exchange, so as to improve the thermal efficiency and drying strength. The dried leaves leave the dryer and then enter the air flow stone tool to remove the impurities. At the same time, they enter the cyclone separator for gas-solid separation. The waste moisture is separated by The fan shall be drawn out and the dry materials shall be discharged through the air shut-off device.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| project | HG-500 | HG-1500 | |

| Water evaporationkg/h) | 360 | 1100 | |

| Production capacity (fresh leaves)(kg/h) | 500 | 1500 | |

| Inlet temperature(℃ ) | ≤ 900 | ≤ 900 | |

| speed(rpm) | 0~11 | 0~11 | |

| Fuel consumptiont(kg/h) | ≤ 60 | ≤ 135 | |

| Total powerr(kw) | 34.4 | 50.39 | |

| Overall dimension of main engine | length(m) | 11 | 12 |

| width(m) | 2 | 2.8 | |

| height(m) | 3.0 | 3.2 | |

| Weight (T) | 20 | 32 | |

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

为开发我国丰富的银杏叶资源,我厂吸收国外先进设备之优点,根据鲜银杏叶的特点,设计并制造了HG 型系列银杏叶烘干设备,为银杏叶深加工打好了良好的基础,彻底解决了鲜银杏叶易腐烂、不易运输和储存的困难,确保了银杏叶的高效成分及色、香、味。并在全国各地成功推广应用。通过用户使用,本生产机组是目前国内^理想的银杏叶、牧草烘干设备。

|  |  |

P

rocess

PROCESS

Reliable supplier of drying equipment users

rocess PROCESS

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION

C

ustomer

CUSTOMER

Reliable supplier of drying equipment users

ustomer CUSTOMER

1. Zhengan ginkgo Development Co., Ltd.

2. Shandong Gaomi ginkgo science and Technology Park

3. Jiangsu Pizhou Fenghua Materials Co., Ltd.

4. Jiangsu Pizhou xialvye Co., Ltd.

5. Sanmenxia Funong ginkgo Development Co., Ltd.

6. Shandong Tancheng Heli Development Co., Ltd.

7. Jiangsu Pizhou City building ginkgo leaf processing factory

8. Jiangsu Pizhou Gangshang ginkgo horticultural factory