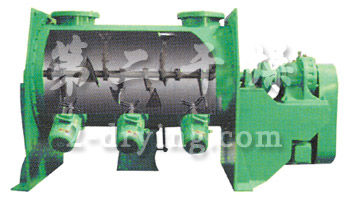

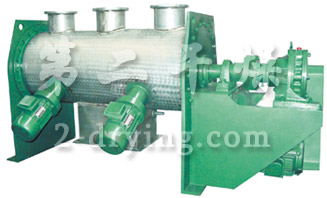

LDH colter mixer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

The machine is composed of four parts: horizontal simplified body, plough, throwing knife and transmission mechanism. Under the action of plough, the material moves in convection along the cylinder wall. When the material flows through the Throwing Knife, it is sheared and sprinkled by the high-speed rotating Throwing Knife, so as to achieve uniform mixing in a short time. It can meet the requirements of most solid-liquid mixing, wet granulation, drying and other composite processes, especially suitable for the mixing of viscous or colloidal materials.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| Item / model | Full volume(m3) | Loading coefficient | power(kw) | size(mm) | weight(kg) |

| LDH-0.1 | 0.1 | 0.4-0.6 | 3 | 1270×865×850 | 430 |

| LDH-0.3 | 0.3 | 0.4-0.6 | 4 | 2070×1050×1150 | 950 |

| LDH-0.5 | 0.5 | 0.4-0.6 | 5.5 | 2180×1200×1300 | 1100 |

| LDH-1 | 1 | 0.4-0.6 | 11 | 2830×1620×1550 | 1800 |

| LDH-2 | 2 | 0.4-0.6 | 18.5 | 3420×1810×1758 | 2520 |

| LDH-3 | 3 | 0.4-0.6 | 18.5 | 3420×2045×1983 | 3200 |

| LDH-4 | 4 | 0.4-0.6 | 22 | 4200×2140×2123 | 4836 |

| LDH-6 | 6 | 0.4-0.6 | 30 | 4680×2290×2448 | 8775 |

| LDH-8 | 8 | 0.4-0.6 | 45 | 5560×2390×2608 | 9360 |

| LDH-10 | 10 | 0.4-0.6 | 55 | 5140×2390×2850 | 9750 |

| LDH-12 | 12 | 0.4-0.6 | 55 | 5720×3110×2960 | 10660 |

| LDH-15 | 15 | 0.4-0.6 | 75 | 5920×3280×3140 | 11050 |

注:1、表中技术参数以物料比重0.6为基准。

2、如有真空、加热、耐压、冷却、干燥、易爆、易燃、易腐蚀等工艺情况时,用户必须明确告知并提供准确相关数据,以文本形式确认后定制。

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

1. The standard product of driving advantage adopts the belt pulley to drive the cycloid reducer. Compared with the large torque of the gear reducer, the elastic connection of the belt drive has the advantage of protecting the transmission parts in case of overload.

2. When the plow blade is running at high speed, it can not only disperse the material axially, but also bring the animal material to flow along the circle of the simplified body. The flying blade in the middle plays an auxiliary role in mixing and mixing.

The effect on the dispersion and depolymerization of agglomerates.

3. The shape and speed of the multi-layer blade are directly connected with the motor. The standard speed is 1440 R / min. according to the difference of material characteristics, there are many shapes and speeds to choose.

4. The atomizing nozzle can be added above the flying knife to realize liquid adding and mixing. Because the density of materials in this position is small under the cutting of flying knife, the liquid materials after atomization are easier to enter and mix with powder materials.

5. The upper part of the standard cylinder is equipped with a feeding port, with a sealing gasket and a cover, and the lock is fastened. The non-standard customization can implement vacuum negative pressure feeding.

6. Discharging mode this type of mixer can also be made into a continuous mixer. By adjusting the opening size of the discharging valve, the residence time of materials in the simplified body can be controlled, so as to achieve the purpose of controlling the mixing uniformity.

User customization

Customize the following structure according to the user's requirements

1. According to the material characteristics, add appropriate configuration, and combine into a drying and mixing integrated system. Drying by conduction heating has the advantages of high efficiency and energy saving.

2. The simplified body can be designed in the form of a jacket, with hot and cold medium introduced to meet the user's requirements for process temperature control.

3. It can be designed to operate under vacuum or pressure conditions. 4. The upper cover, sealing device and discharge valve can be designed according to the user's requirements, and can be manually or pneumatically operated.