CMTY down flow pulse filter

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

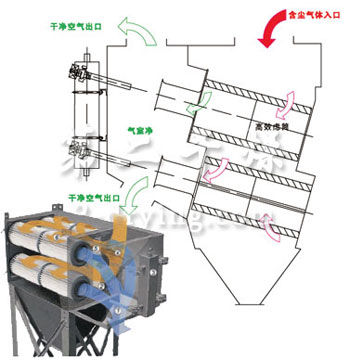

The downflow filter is a new type of dedusting equipment which tilts the filter cartridge, some of the dust containing air flows around the bottom of the filter cartridge to filter, and uses the downflow to improve the dedusting effect. During operation, the dust-containing air enters the filter cartridge dust remover from the top inlet. The larger dust particles will directly settle due to the increase of the cross-sectional area of the equipment and the decrease of the wind speed. The smaller dust particles will be filtered and collected outside the filter cartridge. The filtered clean air will enter the clean air chamber through the center of the filter cartridge and be discharged by the outlet induced draft fan. With the continuous filtration, the dust on the surface of the filter cartridge accumulates. At this time, the air solenoid valve with time sequence will spray 0.5-0.7mpa compressed air in sequence, and the dust gathered on the external surface of the filter cartridge will be blown and vibrated down. The dust will automatically fall off the surface of the filter material under the effect of self weight and air flow, so that the filter cartridge can be regenerated. With the downward main air flow, the dust falls into the dust hopper under the action of gravity and is discharged to ensure the continuous and normal operation of the equipment.

Filter cartridge

The filter material of the filter cartridge dust remover is made of high-tech technology, with special treatment on the surface and certain rigidity. The filter material is folded into a folded cylinder shape, which greatly reduces the volume of the equipment. According to the working conditions, a variety of filter materials can be selected to meet the actual needs. The surface of the filter materials is smooth and hydrophobic. It not only has a good filtering effect on general dust, but also is suitable for certain humidity of gas and sticky dust, which overcomes the problem of the bag filter dust condensation blocking the bag. The utility model can achieve better filtering effect and lower operation cost of the dust remover, and make the filter cartridge more durable.

Concentration and temperature

1. The suitable dust inlet concentration of the dust remover is about 20g / m3, and the inlet concentration of viscous dust is 10g / m3. When the concentration is higher than this, it is suggested to add pre dedusting equipment in the previous stage.

2. The dust remover is suitable for 120oc high temperature. When the temperature exceeds this temperature, high temperature resistant filter material shall be selected or cooling measures shall be taken.

Filtering air speed of filter material barrel

The principle of selecting filtering wind speed is to select lower filtering wind speed for high concentration or viscous dust, and higher filtering wind speed for dry or low concentration dust.

Characteristic

1. The advanced down flow layout and inclined filter tube structure are adopted, so the synchronous dust removal effect of the dust remover is good in the working process.

2. The filter cartridge has a long service life. The dust baffle is set at the dust gas inlet, which has the function of buffering and wear-resisting, and does not make the dust directly impact the filter cartridge at high speed. Every half a year, open the cover plate to rotate the filter cartridge 180 ° along the axis. To change the ash receiving part of the filter material. Effectively prolong the service life of the filter cartridge.

3. It is convenient and quick to replace the filter cartridge. The maintenance is simple. The filter cartridge is 15O, and the inclined plug-in type installation makes the removal and replacement of the filter cartridge more convenient. For general dust, the filter cartridge can be used for a long time without replacement, which saves the tedious work that the common bag filter needs to change and wash the filter bag frequently, and saves a large amount of maintenance costs.

4. It can be cleaned and reused. After long-term use, the filter cartridge can be removed and washed with water or detergent. After drying, it can be reused and cleaned conveniently and quickly.

5. Modular assembly structure combination can be flexibly and conveniently assembled into a whole precipitator to meet different site installation conditions.

6. It can expand the original combination, increase the dust removal unit and air volume of treatment, without too much modification of the original equipment.

7. The equipment is small in size and small in floor area. Compared with the traditional bag filter, it can effectively save the use space.

8. The purification efficiency of the equipment is high, and the selection of appropriate filter materials has a purification efficiency of more than 99% for the dust with micron size.

9. Place the filter cartridge in series with a single cover to ensure the safe operation and convenient maintenance of the equipment.

10. The ash bucket, ash car, screw discharge device and other ash discharging modes can be selected.

11. A variety of filter materials are available for users to choose. According to the industrial and mining requirements, the filter materials with the following characteristics can be selected: flame-retardant composite fiber filter material, flame-retardant treatment polyester fiber, oil and water-proof treatment polyester fiber, anti-static treatment polyester fiber, film covered treatment polyester fiber filter material, etc.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

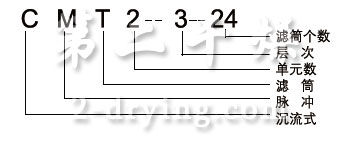

The specification of the dust remover is determined by the number of rows and layers of the filter cartridges. The standard arrangement is: each two rows of filter cartridges is 1 unit, which is 1 unit, 2 layers (8 barrels), 3 layers (12 barrels), 4 layers (16 barrels) and 5 layers (20 barrels). When the processing air volume is large, the number of units can be increased infinitely and arranged in parallel. From unit 3 to unit 8, there are only three and four layers.

Model and specification designation:

Example:

| 型号\技术参数 | 过滤面积 m2 | 处理风量 m3/h | 过滤风速 m/min | 除尘效率 % | 设备阻力 pa | 外形尺寸 长×宽×高 | 设备重量 T |

| CTM1-2-8 | 100 | 4800-7200 | 0.8-1.2 | 99.9 | 800-1200 | 1362×1850×3026 | 1.0 |

| CTM1-3-12 | 150 | 7200-10800 | 0.8-1.2 | 99.9 | 800-1200 | 1362×1850×3476 | 1.3 |

| CTM1-4-16 | 200 | 9600-14400 | 0.8-1.2 | 99.9 | 800-1200 | 1362×1850×3926 | 1.5 |

| CTM2-3-24 | 300 | 14400-21600 | 0.8-1.2 | 99.9 | 800-1200 | 1362×1850×3251 | 2.0 |

| CTM2-4-32 | 400 | 19200-28800 | 0.8-1.2 | 99.9 | 800-1200 | 2100×1850×3701 | 2.5 |

| CTM3-3-36 | 450 | 21600-32400 | 0.8-1.2 | 99.9 | 800-1200 | 3150×1850×3251 | 3.0 |

| CTM4-3-48 | 600 | 28800-43200 | 0.8-1.2 | 99.9 | 800-1200 | 4200×1850×3251 | 4.0 |

| CTM5-3-60 | 750 | 36000-54000 | 0.8-1.2 | 99.9 | 800-1200 | 5250×1850×3701 | 4.8 |

| CTM5-4-80 | 1000 | 48000-75000 | 0.8-1.2 | 99.9 | 800-1200 | 5250×1850×3701 | 5.6 |

| CTM6-3-72 | 900 | 43200-64800 | 0.8-1.2 | 99.9 | 800-1200 | 6300×1850×3251 | 5.6 |

| CTM6-4-96 | 1200 | 57600-286400 | 0.8-1.2 | 99.9 | 800-1200 | 6300×1850×3701 | 6.4 |

| CTM7-3-84 | 1050 | 50400-75600 | 0.8-1.2 | 99.9 | 800-1200 | 7350×1850×3701 | 6.4 |

| CTM7-4-112 | 1400 | 67200-10800 | 0.8-1.2 | 99.9 | 800-1200 | 7350×1850×3251 | 7.5 |

| CTM8-3-96 | 1200 | 57600-86400 | 0.8-1.2 | 99.9 | 800-1200 | 5400×1850×3251 | 7.5 |

| CTM8-4-128 | 1600 | 76800-115200 | 0.8-1.2 | 99.9 | 800-1200 | 8400×1850×3701 | 9.2 |

出料方式

标准的出料方式为插板阀门式集料斗,每个料斗容积0.45m3,人工需定时放料,如果需连续放料,可加设关风器,多台并联可增设螺旋输送机。

订货说明

请客户订货时明确进出风口尺寸技方位,标准供货范围为设备主机,需要平台爬梯、星形卸灰阀、螺旋输送机、风机、管道等须合同中说明,价格另议。