DLG inert particle fluidized bed dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

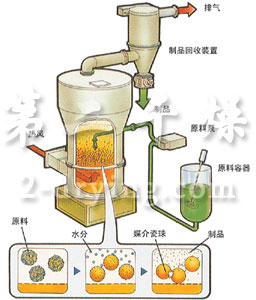

DLG inert particle fluidized bed dryer is a new type of high-efficiency and energy-saving drying device. Based on the ordinary fluidized bed, inert particles, vibration or agitation devices are added to dry the fluidized form. The equipment is mainly used for drying slurry materials.

Introduction to inert particle selection

Glass beads, polytetrafluoroethylene particles, ceramics, quartz sand, alumina balls, zirconia balls, agate balls can be used as inert particles in the fluidized bed.

Inert particles are in the fluidization state in a fluidized bed, and their fluidization performance is affected by their shape, size and density. Generally, inert particles with larger density and particle size tend to crush the dry film on the particle surface, but their fluidization speed is larger, while small particles have larger specific surface volume and better heat transfer performance, but because of their small mass, the collision force is smaller, and they are easy to stick together. The performance of an inert particle fluidized bed is controlled by heat transfer and collision. Therefore, in the selection of inert particles, we should synthesize from many aspects, especially the adhesion of particles of different materials and materials with different properties is also different, so the matching of particles and materials should be properly used, which should be generally determined by experiments.

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

On the inert particles of the chemical layer, a film is formed on the surface of the particles. Under the combined action of hot particles and hot air, the liquid film becomes solid after dehydration. Due to the continuous collision of the fluidized particles under the action of air flow, vibration or agitation device, the solid material film is knocked off into powder shape, and the dried powder material is carried out by the flowing gas, and the powder product is obtained after separation and collection.

In addition to the fluidized bed, there are spouting bed and impinging flow fluidized bed in the device of using inert particles as carrier to dry liquid materials. When the inert particles spouting bed is used to dry liquid materials, it can also make the spouting, film-forming, drying, and powder falling off in an orderly state, while in the fluidized bed, the falling off from spouting liquid to powder is mostly in a random state. Our company is further research and development of inert particle spouted bed and other new technology and new products to better serve our customers.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| Parameter / model | 5 | 25 | 50 | 100 | 150 | 200 | 300 | 500 | 750 | 1000 |

| Rated water evaporation(Kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 300 | 500 | 750 | 1000 |

| Compressed air consumption(m3/min) | 0.2 | 0.3 | 0.4 | 0.6 | 0.9 | 1.1 | 1.6 | 3 | 4.8 | 5.5-15 |

| Inlet temperature(℃) | 50~300Rated as200 | |||||||||

| Heating mode (optional) | Store, steam + electricity, coal (oil) stove | |||||||||

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

Inert particle fluidized bed can be widely used for liquid materials such as suspension and emulsion, viscous materials with low moisture content such as slurry, glue and paste, and paste materials with thixotropy.

Use example:

It can process the following materials: capacitor material, barium titanate, nickel hydroxide, magnetic material, glass powder, metal powder, aluminum oxide powder, titanium oxide, zirconia, calcium carbonate, silicon carbide, calcium silicate, synthetic resin, animal medical treatment, various factory waste liquid.

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

The product can be made into powder similar to primary particle.

The products attached and dried on the surface of the ceramic ball fall off and form powder shape due to the flow and collision of the ceramic balls, so that the products become the powder similar to the primary particles.

High thermal efficiency

Because it is attached to the surface of the ceramic ball and dried, and the film is formed on the surface of the ceramic ball, the critical moisture content of the material is very low. Even with high-temperature hot air, it can keep the product at a low temperature during operation, so the thermal efficiency utilization rate of the device is high.

Large thermal capacity coefficient and miniaturization of the device

The device has the same thermal capacity coefficient as the ordinary fluidized bed dryer, but the device has been miniaturized, and the volume of its drying chamber is only about 1/10-3/10 of the spray dryer.

The device is easy to clean

Because the fluidization drying chamber has the structure of vibration or agitation, it is easy to clean the porous plate and the inside of the drying chamber.

Stable operation

Because the fluidization drying chamber adopts the structure of air flow plus vibration or agitation, the fluidization drying has the advantages of continuous stability, low power and good reliability. Be able to deal with materials with special specifications. When dealing with dried materials containing flammable solvents, be able to deal with them in a closed system.