ZLG vibrating fluidized bed dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

ZLG 振动流化床干燥机广泛适用于化工、轻工、医药、食品、塑料、粮油、矿渣、制盐、糖等行业的粉料颗粒状物料的干燥、冷却、增湿等作业。

| |

ZLG 振动流化床干燥机 ZLG 振动流化床干燥机 |

北京通济达农产品有限公司(ZLG1mx9.5m 直线振动流化床) |

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

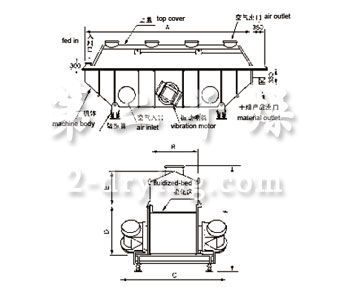

The material enters the machine from the feed inlet. Under the action of the vibration force, the material is thrown along the horizontal direction to move forward continuously. After the hot air passes through the fluidized bed to exchange heat with the wet material, the wet air is discharged from the exhaust outlet after being dedusted by the cyclone separator; the dry material is discharged from the discharge outlet.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| model | Fluidized bed area m2 | Inlet temperature ℃ | Outlet temperature ℃ | Evaporation capacityKg/h | Vibrating motor | |

| type | power | |||||

| ZLG0.30×3 | 0.9 | 70-140 | 40-70 | 20~35 | ZDS10-6 | 0.75×2 |

| ZLG0.30×4.5 | 1.35 | 70-140 | 40-70 | 35~50 | ZDS10-6 | 0.75×2 |

| ZLG0.45×4.5 | 2.025 | 70-140 | 40-70 | 50~70 | ZDS10-6 | 1.1×2 |

| ZLG0.60×4.5 | 2.7 | 70-140 | 40-70 | 70~90 | ZDS10-6 | 1.1×2 |

| ZLG0.45×6 | 2.7 | 70-140 | 40-70 | 80~100 | ZDS10-6 | 1.1×2 |

| ZLG0.60×6 | 3.6 | 70-140 | 40-70 | 100~130 | ZDS25-6 | 1.5×2 |

| ZLG0.75×6 | 4.5 | 70-140 | 40-70 | 120~170 | ZDS25-6 | 1.5×2 |

| ZLG0.9×6 | 5.4 | 70-140 | 40-70 | 140~170 | ZDS30-6 | 2.2×2 |

| ZLG0.6×7.5 | 4.5 | 70-140 | 40-70 | 130~150 | ZDS30-6 | 2.2×2 |

| ZLG0.75×7.5 | 5.625 | 70-140 | 40-70 | 150~180 | ZDS40-6 | 3.0×2 |

| ZLG0.9×7.5 | 6.75 | 70-140 | 40-70 | 160~210 | ZDS40-6 | 3.0×2 |

| ZLG102×8 | 9.6 | 70-140 | 40-70 | 200~280 | ZDS50-6 | 3.7×2 |

| model/size | A | B | C | D | E | F | weight(kg) |

| ZLG0.30×3 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| ZLG0.30×4.5 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1560 |

| ZLG0.45×4.5 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| ZLG0.60×4.5 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1910 |

| ZLG0.45×6 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 200 |

| ZLG0.60×6 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| ZLG0.75×6 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2340 |

| ZLG0.9×6 | 6000 | 900 | 2000 | 1000 | 600 | 1850 | 3160 |

| ZLG0.6×7.5 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| ZLG0.75×7.5 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| ZLG0.9×7.5 | 7500 | 900 | 2100 | 1000 | 600 | 1850 | 4140 |

| ZLG1.2×7.5 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

Driven by vibration motor, it has stable operation, low noise, long service life and convenient maintenance.

It has high thermal efficiency and can save more than 30% energy than general drying device. The bed temperature distribution is uniform without local overheating, fluidization is uniform without dead angle.

The thickness of the material layer and the moving speed and amplitude in the machine can be adjusted steplessly within the design range, with good adjustability and wide application.

It has little damage to the surface of materials, and can be used for drying fragile materials. It can also be used when the particles of materials are irregular, without affecting the effect.

It adopts totally closed structure, effectively prevents cross pollution between materials and the outside world, clean environment, and can work continuously.

When it is used for mass production of high water content materials, multiple sets of series connection can be used to meet the requirements (typical materials: such as polyacrylamide, etc.)

P

rocess

PROCESS

Reliable supplier of drying equipment users

rocess PROCESS

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION