ZLPG spray dryer for Chinese medicine extract

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

The spray dryer for Chinese medicine extract is a drying equipment which is developed for foreign technology and is suitable for Chinese medicine products with low melting point and high sugar content. According to the characteristics and properties of drying products, the device determines the spray drying process conditions, with high automation and convenient operation, which is in line with the requirements of GMP. The successful development of this equipment has solved many difficulties in many years that many traditional Chinese medicine products with low melting point and high sugar content can not be spray dried, and is also a new development in the application technology research of spray drying in the pharmaceutical industry of traditional Chinese medicine.

|  |

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

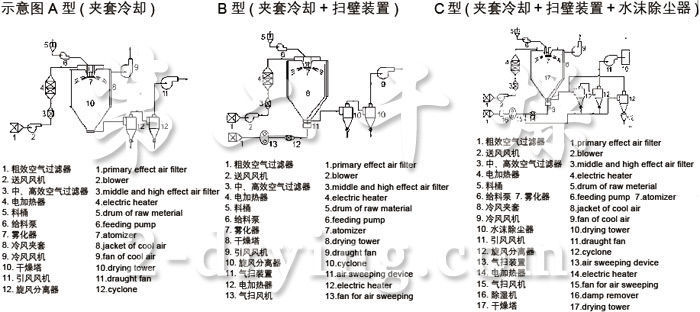

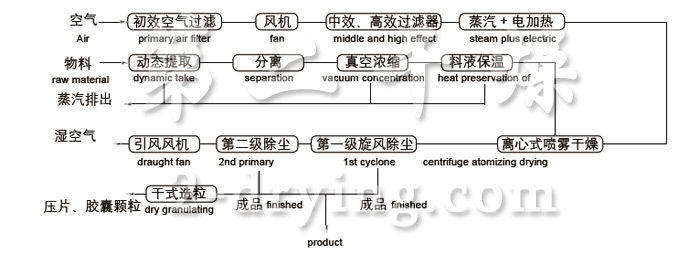

The high speed centrifugal spray device of Chinese medicine extract is the application of centrifugal spray drying technology in the drying of specific materials. It is also a drying device for making instant powder drying and forming powder products by using high speed centrifugal atomizer to disperse materials into thin air and fully contact with hot air. The drying equipment is specially used to solve the spray dryer of Chinese medicine extract and plant extract. It effectively solves many problems of the original LPG high speed spray dryer in the drying of Chinese medicine extract. Compared with the original LPG centrifugal spray dryer, it has the following characteristics:

1. In order to prevent the material from sticking to the wall, the equipment is equipped with air sweep wall and tower wall jacket cooling structure to effectively prevent the product from sticking to the wall and coking. Improve product quality and yield.

2. The special air delivery system for finished products can separate the dried products from the hot and humid air in the system in time, so as to avoid the possibility of moisture absorption and moisture regain agglomeration of finished products.

3. The air entering the dryer is purified by three levels of air, so that the air inlet can meet the requirements of 300000 levels;

4. Adopt quick opening and washing device, which is suitable for various production requirements;

5. Material collection adopts two-stage cyclone dust removal device or one-stage cyclone dust removal + wet dust remover;

6. The volume and configuration of the spray tower should be adjusted according to the nature of the material to make it more practical.

7. PLC control and program control system screen display are available;

8. The whole drying system is designed and manufactured in accordance with GMP specifications;

9. Users can choose one of type A, type B and type C according to the material characteristics when ordering to achieve good adaptability between equipment and materials.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| model | ZLPG- 13 | ZLPG- 17 | ZLPG- 25 | ZLPG- 32 | ZLPG- 38 | ZLPG- 40 | ZLPG- 47 | ZLPG- 52 | ZLPG- 58 | |

| Water evaporationkg/h | 5 | 10 | 25 | 50 | 80 | 100 | 150 | 200 | 300 | |

| Liquid handling capacity(kg/h) | 6-7 | 12-14 | 25-34 | 50-68 | 80-108 | 100-135 | 150-203 | 200-270 | 300-406 | |

| Output of finished products(kg/h) | 1-2 | 2-4 | 4.8-7.2 | 9.2-14 | 14.8-22.4 | 18.4-28 | 28-42 | 36.8-56.4 | 55-85 | |

| Solid content of wet material (%) | 18~25 | |||||||||

| Moisture content of finished product(%) | 3~5 | |||||||||

| electric power(kw) | 36 | 45 | 63 | 99 | 132 | 153 | 204 | 246 | 330 | |

| Heating source | Steam + electricity | |||||||||

| Product capture mode and efficiency | Secondary cyclone or primary cyclone and primary wet deduster ≥ 95% | |||||||||

| Automatic control instrument | Hot air temperature and exhaust temperature indication, automatic adjustment temperature controller | |||||||||

| Inlet temperature (℃ ) | 150~200 | |||||||||

| Outlet temperature (℃ ) | 80~100 | |||||||||

| size (mm) | length | 5000 | 5500 | 7000 | 8000 | 9800 | 11000 | 12200 | 14100 | 15000 |

| wdth | 3000 | 3500 | 4000 | 5000 | 5700 | 6200 | 7000 | 7800 | 9000 | |

| jeight | 4500 | 4600 | 5200 | 6500 | 7600 | 8100 | 9000 | 9850 | 11100 | |

The design conditions of this table: 1. The inlet temperature is 220 ℃, the outlet temperature is 85 ℃; 2. The steam pressure is 0.6MPa; 3. According to the user's requirements, the vibrator, air scanning device and cooling jacket can be installed.

P

rocess

PROCESS

Reliable supplier of drying equipment users

rocess PROCESS

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION