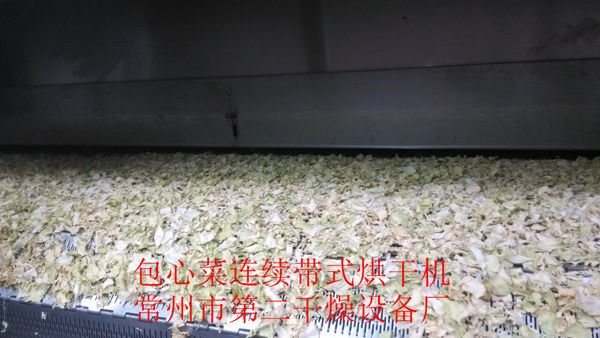

DWD belt dehydrated vegetable dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

DWD dehydration dryer is a special equipment developed on the basis of traditional mesh belt dryer. It has strong pertinence, practicability and high energy efficiency. It is widely used for dehydration and drying of all kinds of regional and seasonal vegetables and fruits. For example: garlic slice, pumpkin, konjac, radish, yam, bamboo shoot, etc. Since 1993, our factory has jointly developed and produced the first net belt vegetable dryer for dehydration and drying of pumpkins in China with the Chinese Academy of Sciences. In that year, we sold five production lines in China. So far, we have more than 50 users and more than 80 sets of online equipment in China. We are an experienced vegetable drying equipment manufacturer in China. Our scientific and technological personnel have been tracking and serving for a long time. Some users, in-depth user debugging research, get first-hand practical information and combined with foreign advanced technology, continue to improve and improve the equipment. So far, we have developed to the third generation of DWD series vegetable dehydration dryer. When we manufacture equipment for users, we design and manufacture suitable and high-quality vegetable drying equipment for users according to the characteristics of the required drying products, the user's process requirements and the experience accumulated in decades. This series of equipment has been patented.

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

Vegetable dehydration dryer is composed of feeder, drying bed, heat exchanger and exhaust fan.

When the dryer works, the cold air is heated by the heat exchanger, and the scientific and reasonable circulation mode is adopted to make the hot air flow through the dried materials on the bed surface for uniform heat and mass exchange. The hot air in each unit of the body circulates under the action of the circulation fan, and then the air with low temperature and high humidity is discharged, so as to complete the whole drying process smoothly and efficiently.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| model | DWT1.6-Ⅰ | DWT1.6-Ⅱ | DWT1.6-Ⅲ | DWT-2-Ⅰ | DWT-2-Ⅱ | DWT-2-Ⅲ |

| Network bandwidth(m) | 1.6 | 1.6 | 1.6 | 2 | 2 | 2 |

| Drying section length(m) | 10 | 10 | 8 | 10 | 10 | 8 |

| Paving thickness(mm) | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

| Service temperature(℃) | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ | 50-150℃ |

| Heat transfer area(m2) | 525 | 398 | 262.5 | 656 | 497 | 327.5 |

| Steam pressure(Mpa) | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 |

| drying time(h) | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 |

| Transmission power(kw) | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| size(m) | 12×2.5 ×1. 9 | 12×2.5 ×1. 9 | 10×2.5 ×1. 9 | 12×2.9 ×l.92 | 12×2.9 ×l.92 | 12×2.9 ×l.92 |

Note: 1. Three sets of mesh belt dryer feeding platform, middle platform and discharge platform of the same specification in the above table are used in series to ensure the production process requirements of vegetable dehydration and drying, significantly improve the output and effectively guarantee the product quality. 2. The height of equipment does not include the height of fan and air duct.

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

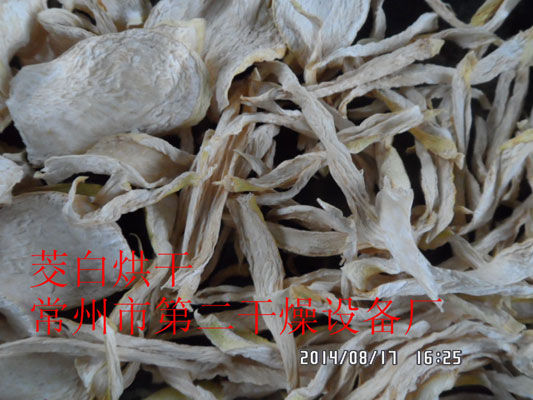

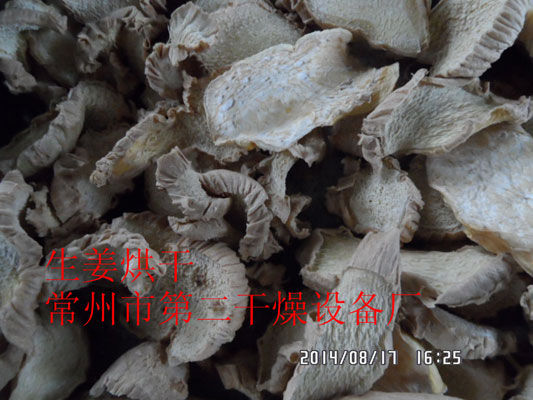

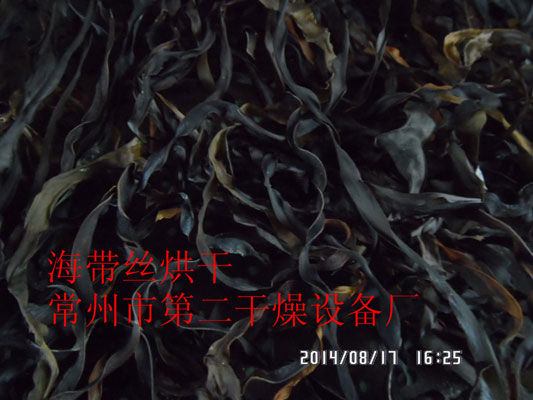

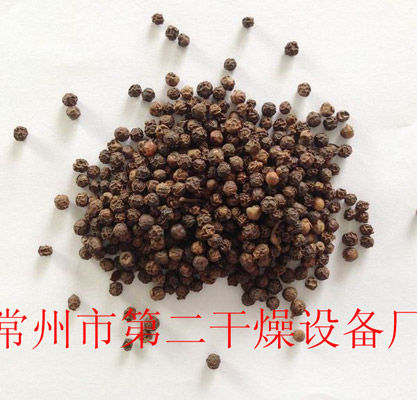

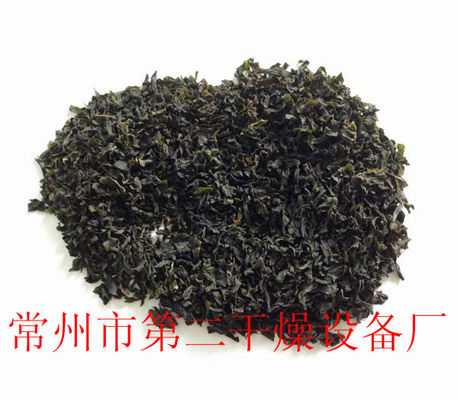

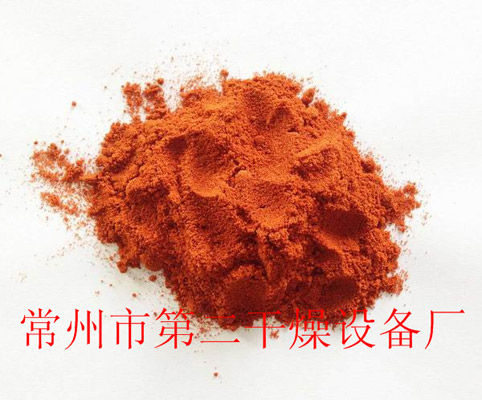

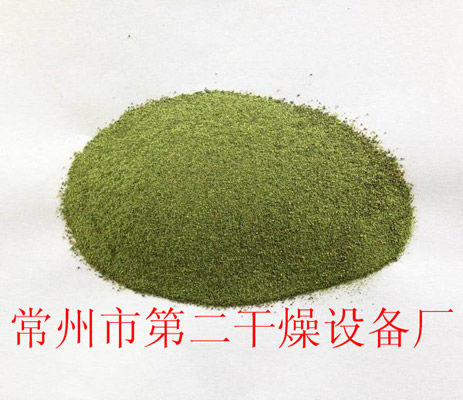

It can meet the requirements of drying and mass continuous production of vegetable materials such as roots, stems, leaves, strips, blocks, flakes, large granules, etc., and can retain the nutritional ingredients and colors of products to a large extent.

The typical drying materials are: garlic slice, pumpkin, carrot, konjac, yam, bamboo shoot, horseradish, onion, apple, etc.

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

The drying area, air pressure, air volume and drying temperature can be adjusted to meet the characteristics and quality requirements of vegetables.

According to the characteristics of vegetables, different technological processes and necessary auxiliary equipment can be used.

Applicable materials of the equipment are as follows:

Kelp, laver, coffee bean, sesame, pepper, pepper, parsley, litchi, Guiyuan, gluten, taro, walnut, white potato, purple sweet potato, sweet potato, chestnut, chestnut, preservative, food, carrageenan, shrimp, shrimp, cauliflower, fourth quarter bean, green bean, potato, fungus, renlang, oyster, squid, sea cucumber, abalone, jellyfish skin, horseradish, tofu Skin, nuts, wild vegetables, tomatoes, strawberries, blueberries, plum, blackberry, sour dates, hawthorn, hickory, mango slices, coconut meat, pineapple, water bamboo, Hami melon, etc.

P

rocess

PROCESS

Reliable supplier of drying equipment users

rocess PROCESS

C

ustomer

CUSTOMER

Reliable supplier of drying equipment users

ustomer CUSTOMER

1. Yantai Wuzhou organic farm Co., Ltd. 2mx13m (4 sets)

2. Fujian Fuji Island (Zhenghe) Food Co., Ltd. 2mx10m (6 sets)

3. Shandong Jinxiang Tianda Green Food Co., Ltd. 2mx10m (6 sets)

4. Hebei Hengshui Shanzhi Health Products Co., Ltd. 2mx10m (8 sets)

5. Jiangxi Nancheng Huaishan Food Co., Ltd. 2mx10m (3 sets)

6. Yunnan Shiping Dongsheng Food Co., Ltd. 2mx10m (6 sets)

7. China Academy of agricultural machinery (Xiaolihe township government, Yumen, Gansu) 2mx10m (3 sets)

8. Zhejiang Hangzhou Baiwen Food Co., Ltd. 2mx10m (1 set)