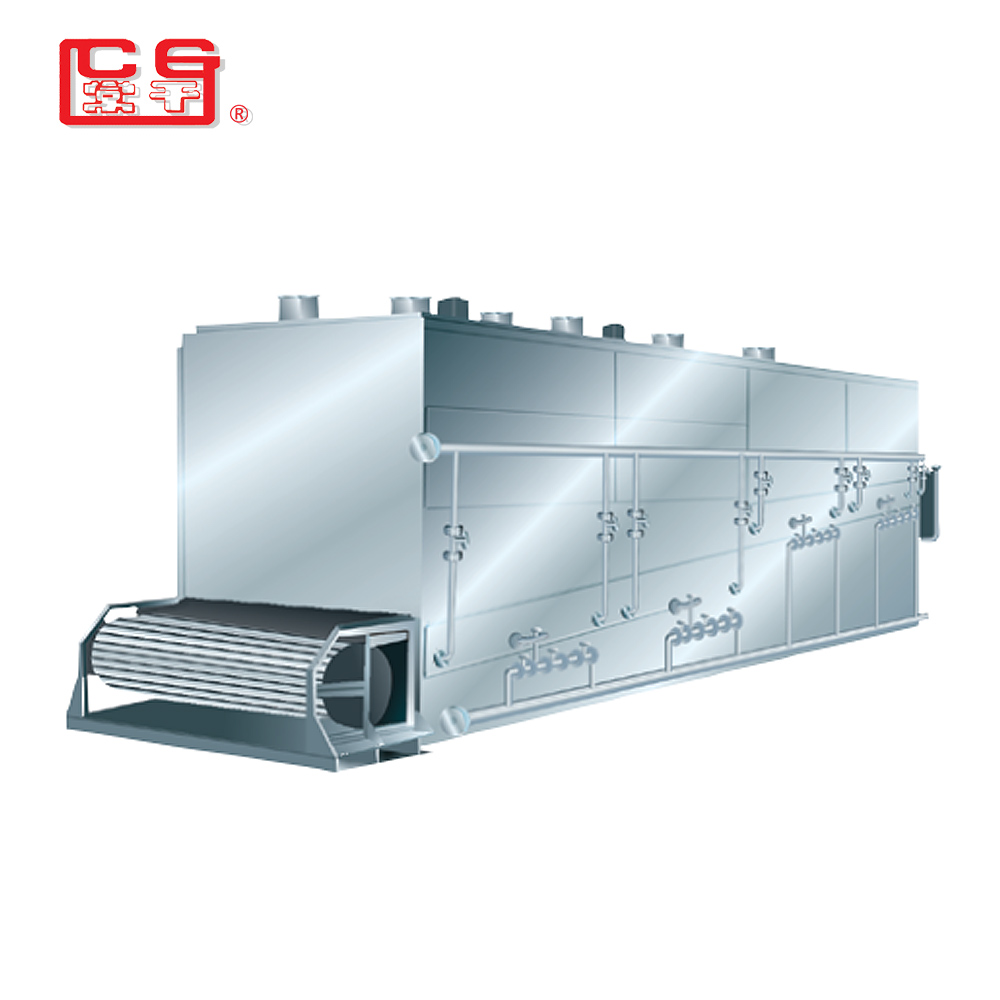

DWT series belt dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

DWT series belt dryer is the second generation belt dryer developed and produced by our company. The main structure of the equipment is to place the heat exchanger on the upper and lower position of the mesh belt. The hot air circulation mode is longitudinal multi unit series circulation, which has the advantages of uniform heating and high heat utilization rate.

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

The principle is as shown in the figure, the material in the hopper is evenly paved on the stainless steel wire mesh (4) by the feeder (6), and the belt is driven by the drive motor to move at a constant speed in the drying box. The drying section is composed of several units. The hot air circulates longitudinally in two (or several) units. The fresh air enters through the fan (1), and is heated by the heat exchanger (3). The hot air passes through the material layer and exchanges heat with the material, then enters the lower chamber, and flows to the next unit. The cooled hot air is then reheated by the heat exchanger (3), and the hot air penetrates through the mesh belt and exchanges heat with the material again, which is humid and hot. Air from exhaust fan (2) (5)

Discharge and finish drying. The number of units of each dryer can be selected according to the material characteristics and process requirements.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 |

| Cell number | 4 | 5 | 4 | 5 | 4 | 5 |

| bandwidth(m) | 1.2 | 1.6 | 2 | |||

| Drying section length(m) | 8 | 10 | 8 | 10 | 8 | 10 |

| Paving thickness(mm) | 10-80 | |||||

| Service temperature(oC) | 60-150 | |||||

| Steam pressure(MPa) | 0.2-0.8 | |||||

| Steam consumption(kg/h) | 120-300 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 |

| drying time (h) | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 |

| Drying intensity kg水/h | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 |

| Total power of fan (kw) | 8.8 | 11 | 12 | 15 | 16 | 20 |

| Total power of equipment (kw) | 10.1 | 12.3 | 13.3 | 16.3 | 17.3 | 21.3 |

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

DWT series belt dryer is the second generation belt dryer developed and produced by our company. The main structure of the equipment is to place the heat exchanger on the upper and lower position of the mesh belt. The hot air circulation mode is longitudinal multi unit series circulation, which has the advantages of uniform heating and high heat utilization rate. It can be used for drying flaky, granular and strip materials with good air permeability. It has the advantages of fast drying speed and high evaporation intensity for the materials with high water content and no small particles such as Chinese herbal pieces and some vegetables.

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

Advantages: the heat exchanger is placed on the upper and lower positions of the mesh belt for uniform heating and high thermal efficiency. It can be used in series with multiple units to effectively increase the drying area.

Disadvantages: it is not suitable for powder materials easily produced in the drying process.

Applicable materials of the equipment are as follows:

Kelp, laver, coffee bean, sesame, pepper, pepper, parsley, litchi, Guiyuan, gluten, taro, walnut, white potato, purple sweet potato, sweet potato, chestnut, chestnut, preservative, food, carrageenan, shrimp, shrimp, cauliflower, fourth quarter bean, green bean, potato, fungus, renlang, oyster, squid, sea cucumber, abalone, jellyfish skin, horseradish, tofu Skin, nuts, wild vegetables, tomatoes, strawberries, blueberries, plum, blackberry, sour dates, hawthorn, hickory, mango slices, coconut meat, pineapple, water bamboo, Hami melon, etc.