DWD series belt dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

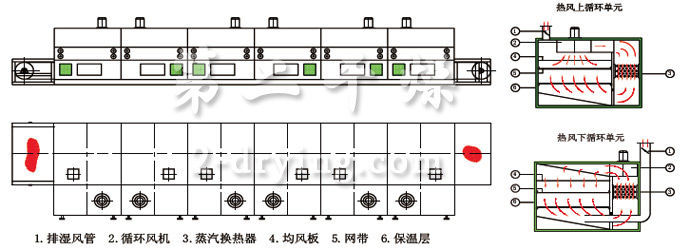

DWD series belt dryer is the third generation belt dryer developed and produced by our company on the basis of the second generation DWT belt dryer according to many years of practical experience and combined with the advanced technology of similar products at home and abroad. This machine overcomes the shortcomings of DWT series equipment in the actual use of some materials, makes the structure of belt dryer more perfect and reasonable, the scope of application is wider, the operation is stable and convenient, and the thermal efficiency is high. The main structural features are as follows: 1. The heat exchanger is arranged separately from the mesh belt drying chamber, and a heat exchanger chamber is arranged on the side of the drying chamber to effectively avoid the bad contact between the powder particles and the heat exchanger (such as the problem that the loss of the powder particles affects the heat exchange effect on the heat exchanger). 2. The hot air circulation mode is changed from the longitudinal multi unit series flow to the lateral unit circulation, realizing the independent circulation of each unit, forced ventilation, effectively increasing the circulating air volume, bringing many advantages, such as high penetration of hot air, high heat utilization rate, good unit controllability, etc., with high stability and high efficiency and energy saving. It is an ideal and reliable production equipment for the majority of users.

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

The material to be dried is evenly distributed on the adjustable speed mesh belt through a suitable feeding device. During drying, the hot air flows through the gap between the mesh belt and the material through the upper and lower parts, making each surface of the dried material become a heating surface, significantly increasing the heat exchange contact area between the material and the hot air, and shortening the evaporation and diffusion distance of the internal moisture of the material. Therefore, it can Excellent drying operation. The way of independent horizontal circulation of hot air unit makes the hot air more penetrating, the control of temperature and air volume more flexible and convenient, so it has more extensive adaptability with different kinds and properties of materials.

T

XPLAINATION

TECHNICAL

Reliable supplier of drying equipment users

XPLAINATION TECHNICAL

In the process of practical use, we realize that it is unreasonable to solve the drying of various materials with different properties and requirements in a design way. Therefore, DWD series equipment emphasizes its specificity on the basis of finali

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| Item / model | DWDl.2×8 | DWDl.2×10 | DWDl.6×8 | DWDl.6×10 | DWD2×8 | DWD2×10 |

| Drying area(m2) | 9.6 | 12 | 12.8 | 16 | 16 | 20 |

| Drying section length × bandwidth (m) | 1.2×8 | 1.2×10 | 1.6×8 | 1.6×10 | 2×8 | 2×10 |

| Cell number | 4 | 5 | 4 | 5 | 4 | 5 |

| Service temperature (℃) | 50-150 | |||||

| Steam working pressure(Mpa) | 0.2-0.6 | |||||

| Steam consumption (Kg/h) | 120-250 | 150-375 | 150-375 | 170-470 | 225-600 | 450-1200 |

| drying time(h) | 0.2-1.5 | 0.25-1.5 | 0.2-1.5 | 0.25-1.5 | 0.2-1.5 | 0.25-1.5 |

| Evaporation capacity (Kg/H20) | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 |

| Installed capacity (kW) | 11.4 | 13.6 | 11.4 | 13.6 | 19.7 | 21.7 |

| Outline size (L×W×H)(m) | 9.77×1.5 ×2.83 | 11.77×1.5 ×2.83 | 9.77×2.44 ×2.83 | 11.77×2.24 ×2.83 | 9.77×2.66 ×3.50 | 11.77×2.66 ×3.50 |

| weight(Kg) | 4800 | 5780 | 5400 | 6550 | 6350 | 7800 |

Note: 1. The user should select the type according to the output, material moisture content and other parameters.

2. Increase the drying area in series with several or more sets to meet the use requirements and improve the output and quality of products.

3. The conveyor belt of standard model is stainless steel wire mesh. Users can select stainless steel chain plate steel belt, stainless steel mesh belt and polytetrafluoroethylene non stick mesh belt according to their needs.

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

Widely used in food, chemical, pharmaceutical, feed, pigment, dye, mineral products, building materials and other industries, granular, block, sheet, crystal, filter cake like material drying.

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

The heat exchanger is arranged separately from the mesh belt drying chamber, and a heat exchanger chamber is arranged on the side of the drying chamber to effectively avoid the bad contact between the material particles and the heat exchanger.

The hot air circulation mode is changed from the longitudinal multi unit series flow to the lateral unit circulation, realizing the independent circulation control of each unit, effectively increasing the circulation air volume, bringing many advantages such as high hot air penetration, high heat utilization rate, high efficiency and energy saving, flexible unit control and good controllability.

Do not damage the shape of the material, the material in the dryer is moving in a static state, will not produce the phenomenon of mechanical damage to the shape of the material.

The user can set appropriate operation conditions, and flexibly adjust the temperature, air volume, mesh belt operation speed and other operating conditions according to the hot air circulation mode and drying state.

Adjust the moisture content of the finished product of the material freely. Since the material flow and residence time in the dryer can be adjusted freely, the moisture content of the processed product can be set arbitrarily.

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION

C

ONFIGURATION

CONFIGURATION

Reliable supplier of drying equipment users

ONFIGURATION CONFIGURATION

It can be equipped with many kinds of conveyor belts. According to the requirements of material properties, it can choose various kinds of conveyor belts, such as stainless steel grid mesh, special-shaped mesh, stainless steel punched steel plate belt, etc. (Note: the standard equipment is stainless steel wire mesh)

It can be equipped with a dust remover. When some small particles or powder materials are dried, a small amount of dust will fly. It can be collected and treated by a cyclone or a bag water film.

The bottom plate cleaning device can be configured to clean and scrape a small amount of materials falling on the bottom plate to the discharge end.

Flexible combination, according to the different moisture content of material output, multiple equipment can be used in series to improve the output.

It can be equipped with cleaning device. According to the characteristics of the material when it is dry, it can be equipped with various structures of mesh belt cleaning mechanism to effectively clean the bonded material on the mesh belt.

The conveyor belt cleaning device can be configured. According to the material properties and requirements, the bottom conveyor belt can be placed under the drying and heating outdoor for spray cleaning.

It can be equipped with various forms of pre forming equipment. Some small powder, paste and paste materials can only be dried after pre forming. The company provides a series of forming equipment.