Whlh horizontal rotary screw belt double motion mixer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

In the long-term production practice of our company, this product sums up many problems existing in the actual use and operation of the mixing equipment and the solutions and experience, while a new type of mixing equipment is developed and produced, which combines the reasonable advantages of the traditional rotary and mixing forms, overcomes the disadvantages of a single mixing method, and expands the two mixing methods. The method has the advantages of high efficiency and high quality. The mixer has wide adaptability to various materials with different properties and mixing requirements, convenient and reliable operation, and ideal mixing effect.

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

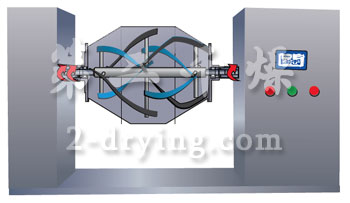

The horizontal rotary screw belt double motion mixer is composed of a horizontal rotating double cone rotary barrel and a screw belt blade (or blade) assembly rotating inside the barrel. According to the need, the cylinder and the screw belt (blade) can be driven by a separate power system, or they can be driven by their own independent power system, which has better control performance. The rotary barrel and the inner rotating shaft are sealed by special sealing components. When discharging, the discharging port is set down, and the discharging is accelerated by stirring the spiral belt blade.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| model | Barrel volume(L) | Large charge volume(L) | Large charge weight (kg) | power (kw) | size (mm) | weight (kg) | ||

| Barrel rotation speed(r/min) | Blade speed(r/min) | |||||||

| WHLH-50 | 50 | 35 | 60 | 12 | 48 | 1.1 | 1160×660×890 | 420 |

| WHLH-200 | 200 | 140 | 240 | 10 | 38 | 2.2 | 1560×780×1160 | 640 |

| WHLH-400 | 400 | 280 | 480 | 10 | 38 | 3.0 | 1960×900×1430 | 860 |

| WHLH-600 | 600 | 420 | 720 | 9.5 | 34 | 4.0 | 2400×1000×1700 | 1070 |

| WHLH-800 | 800 | 560 | 960 | 8.5 | 34 | 5.5 | 2800×1120×1970 | 1290 |

| WHLH-1000 | 1000 | 700 | 1200 | 7 | 29 | 7.5 | 3000×1240×2100 | 1430 |

| WHLH-1500 | 1500 | 1050 | 1800 | 7 | 29 | 11 | 3460×1450×2320 | 1950 |

| WHLH-2000 | 2000 | 1400 | 2400 | 7 | 29 | 15 | 4000×1770×2550 | 2640 |

| WHLH-3000 | 3000 | 2100 | 3600 | 6 | 29 | 22 | 4620×2190×3150 | 3470 |

Note: when ordering, the user shall indicate the drive mixing mode: A: the drive of cylinder and screw belt (paddle) is driven by a separate power system. B: the drive of cylinder and screw belt adopts independent power system.

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

1. It is widely used in the mixing of dry powder or semi-dry powder materials in pharmaceutical, food, chemical, powder metallurgy, rare earth and other industries.

2. High mixing efficiency, especially suitable for materials with high mixing uniformity requirements.

3. Suitable for mixing of fine powder, ultra-fine powder and materials with large specific gravity difference.

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

1. Rotating the barrel can eliminate the dead angle of materials, accelerate the mixing of materials, and make the mixing more sufficient.

2. The blade of spiral belt (blade) with relatively fast speed in the barrel plays the main role of mixing. When the internal and external inner rings of the spiral blade rotate, the material will be stirred radially and moved from the middle to both ends at the same time. When the outer ring spiral belt rotates, the material is moved radially from both ends to the middle at the same time, so that the material can roll radially and have transverse convection at the same time, making the mixing more uniform. The rotating movement of the shell makes the material tumble and mix by convection, and the shear, impact, convection and other effects of the spiral blade on the powder make the mixing efficiency of the equipment very high. Compared with the ordinary mixer, the mixing time can be shortened and the mixing uniformity can be effectively improved.

3. The mixer has a better mixing effect on the powder with large specific gravity difference. Because the screw belt blade in the mixer has a downward pressure action on the powder when it rotates, the light powder floating on the top can be pressed into the heavy powder to achieve full mixing of light and heavy.

4. According to the material characteristics and mixing requirements, there are many types of mixed screw belts or blades available.