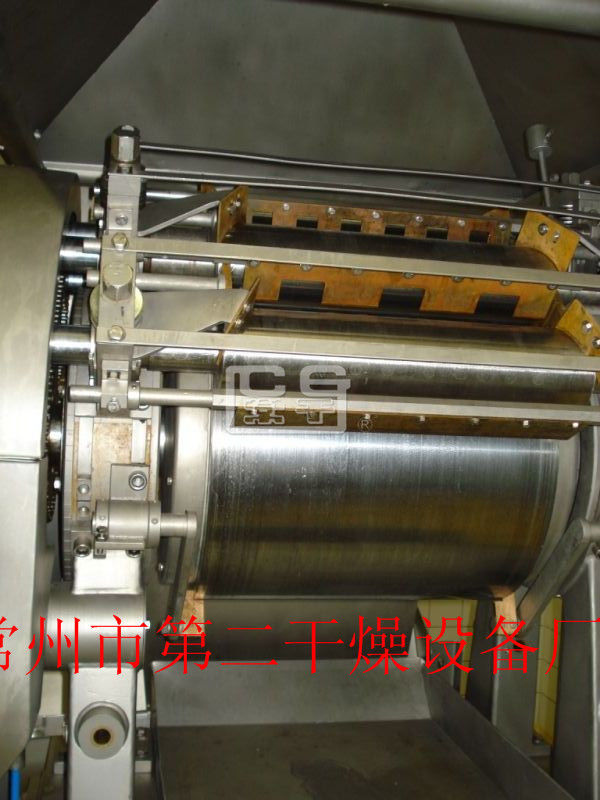

Hg scraper drum dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

The working principle of Hg series scraper drum dryer is to make liquid or slurry materials form film on the surface of drum heated by water vapor or other heat carriers, and then dry them in the process of turning the drum for one circle. Use scraper to scrape off the products, expose the surface of drum and contact with raw materials again to form film for drying.

|  |

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| Parameters / specifications | Ø800×1600 | Ø1000×2000 | Ø1200×2000 | Ø1400×2400 | Ø1600×2400 |

| Heat source pressureMpa | ≤0.6 | ||||

| Main motor powerKW | 3 | 4 | 4 | 5.5 | 7.5 |

| Heat transfer area ㎡ | 4 | 6.2 | 7.5 | 10.5 | 12 |

| Drum speed rpm | 0.5-5 | ||||

| Work heat source | Steam, heat transfer oil | ||||

| Feeding mode | Top or bottom | ||||

| Evaporation capacity | 15-55kg/㎡.h | ||||

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

It is suitable for the production and drying of sticky and paste materials in food, chemical and pharmaceutical industries.

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

With steam or heat transfer oil as heat source, the heating area is large, the heat efficiency is high and the heating is even.

The heat and mass transfer process of the wet film on the cylinder wall is the same from the inside to the outside, the temperature gradient is large, and the evaporation intensity of the film surface is high.

Short drying time, suitable for heat sensitive materials, easy to operate and maintain.