JYS series paddle dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

In recent years, energy conservation and environmental protection have penetrated into all walks of life. For drying, energy conservation and environmental protection means improving equipment process, improving equipment performance and reasonable use of energy, reducing exhaust emissions and tail gas treatment, and reaching relevant standards.

The difference between the paddle dryer and other dryers is that it is a conductive energy-saving drying equipment, which can be used in the fields of chemical industry, food, petrochemical industry, pharmaceutical industry, environmental protection, etc. to indirectly heat or cool paste, granule and powder slurry materials, to complete the heating, drying, cooling and other operations. In special cases, it can also dry heat sensitive materials and recover solvents in the drying process.

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

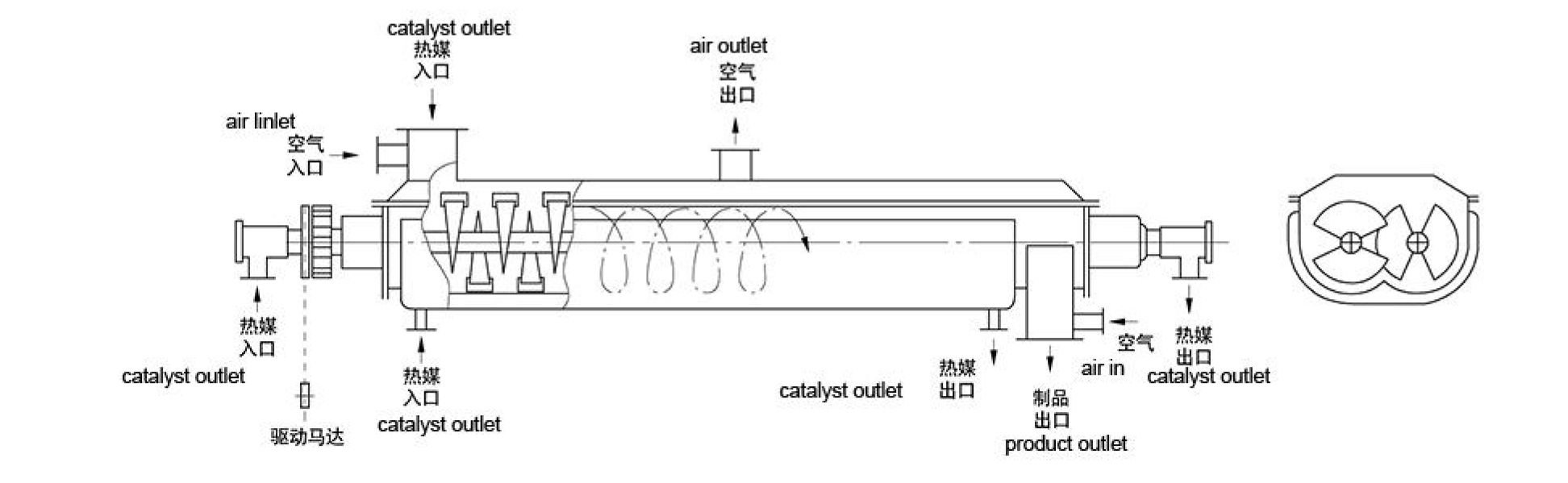

The dryer uses steam, hot water or heat-transfer oil as heating medium, and the shaft end is equipped with a rotary joint for introducing and exporting the hot medium. The heating medium is divided into two ways, which respectively enter the jacket of the drying shell and the inner cavity of the propeller blade shaft to heat the body and the propeller blade shaft at the same time to heat and dry the materials in the way of conduction heating. Be dry

The materials are continuously fed into the feeding port of the dryer by the screw feeder. The materials enter the rear of the dryer. The rotation of the paddle makes the materials turn over and agitate to update the heating interface continuously. The contact with the body and paddle is fully heated, which makes the surface moisture contained in the materials evaporate. At the same time, the material turns into a spiral with the rotation of the propeller blade shaft.

The trajectory is conveyed to the discharge port, and the mixing is continued during the conveying, so that the water exuded from the sludge continues to evaporate. Finally, the qualified products dried evenly are discharged from the discharge port.

Wedge-shaped hollow blades are densely arranged on the hollow shaft, and the thermal medium flows through the blades through the hollow shaft. The unit effective volume has a large heat transfer area. The temperature of the thermal medium ranges from - 20 ℃ to 344 ℃, which can be water vapor or liquid type: such as hot water, heat transfer oil, etc. Indirect conduction heating ﹖ does not carry air to remove heat and heat

They are used to heat materials. The heat loss is only the heat dissipation to the environment through the insulation layer of the reactor body. The heat transfer surface of wedge blade has self-cleaning function. The relative movement of the material particles and the wedge-shaped surface produces the washing effect, which can wash off the attached materials on the wedge-shaped surface, and keep the clean heat transfer surface during the operation. Shell of paddle dryer

The body is U-shaped, and two to four hollow stirring shafts are generally arranged in the shell. The shell is provided with a sealed end cover and an upper cover to prevent the material dust from leaking out.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

Petrochemical Industry: polyolefin powder, polycarbonate vinegar resin, high and low density polyethylene, linear low density polyethylene, polycondensal particles, nylon 6, nylon 66, nylon 12, acetate fiber, polyphenylene sulfide, acrylic resin, engineering plastics, PVC, polyvinyl alcohol, polystyrene, polypropylene, polyester, POM, styrene, acrylonitrile copolymerization, ethylene and Propylene Copolymerization Gather.

Environmental protection industry: PTA sludge, electroplating sewage sludge, boiler ash, pharmaceutical waste, sugar plant waste, monosodium glutamate plant waste, coal ash.

Feed industry: soy sauce residue, bone based feed, distiller's grains, leftover food, apple residue, orange peel, soybean meal, chicken bone feed, fish meal, feed additive, biological residue mud.

Food industry: starch, cocoa bean, corn, salt, denatured starch, medicine.

Chemical industry: soda ash, NPK compound fertilizer, kaolin, bentonite, white carbon black, carbon black phosphorite, sodium fluoride, calcium nitrate, magnesium carbonate, sodium olivide, aluminum hydroxide, barium sulfate, calcium sulfate, calcium carbonate, dye, molecular sieve, soap turbulence.

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

Low energy consumption of paddle dryer: due to indirect heating, there is no large amount of air to take away heat from the outer wall of the dryer, and a thermal insulation layer is set up. For paddle like materials, only 1.2-1.5kg water vapor is needed for evaporation of 1kg water.

Flexible operation: easy control and strong applicability. The gradient of temperature, humidity and mixing degree of the material in the axial range is very small, and the process is stable. The residence time of the material can be precisely adjusted by adjusting the rotating speed of the main engine.

Wide range of materials to be treated: different heat media can be used to treat heat sensitive materials and materials requiring high temperature treatment. Common media are: steam, heat transfer oil, hot water, cooling water, etc. Both continuous operation and intermittent operation can be used in many fields.

Small environmental pollution: Little entrainment of materials without carrying air dust. The evaporation capacity of the material solvent is very small for treatment. Closed circuit circulation can be used for contaminated materials or solvent to be recovered.

Low operating cost: structure. Small wear and maintenance costs are very low.

The operation stability is due to the special compression expansion mixing action of wedge blade.

The material particles are in full contact with the heat transfer surface, and the gradient of temperature, humidity and mixing degree of the material in the axial range is very small, thus ensuring the stability of the process.

P

rocess

PROCESS

Reliable supplier of drying equipment users

rocess PROCESS

Low energy consumption of paddle dryer: due to indirect heating, there is no large amount of air to take away heat from the outer wall of the dryer, and a thermal insulation layer is set up. For paddle like materials, only 1.2-1.5kg water vapor is needed for evaporation of 1kg water.

Flexible operation: easy control and strong applicability. The gradient of temperature, humidity and mixing degree of the material in the axial range is very small, and the process is stable. The residence time of the material can be precisely adjusted by adjusting the rotating speed of the main engine.

Wide range of materials to be treated: different heat media can be used to treat heat sensitive materials and materials requiring high temperature treatment. Common media are: steam, heat transfer oil, hot water, cooling water, etc. Both continuous operation and intermittent operation can be used in many fields.

Small environmental pollution: Little entrainment of materials without carrying air dust. The evaporation capacity of the material solvent is very small for treatment. Closed circuit circulation can be used for contaminated materials or solvent to be recovered.

Low operating cost: structure. Small wear and maintenance costs are very low.

The operation stability is due to the special compression expansion mixing action of wedge blade.

The material particles are in full contact with the heat transfer surface, and the gradient of temperature, humidity and mixing degree of the material in the axial range is very small, thus ensuring the stability of the process.

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION