QG, FG, GFF series air dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

Air dryer, also known as instant and flash dryer, has been used in pharmaceutical and chemical industries since 1960s. Since the establishment of our factory, we have introduced excellent technology to provide high-quality air drying equipment for pharmaceutical, chemical, food and other industries. Over the past decade, we have continuously improved, improved and developed the following three series of air dryer: QG series, FG series and GFF series.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

QG系列

model | moisture to be evaporatedkg/h | equipped power(kw) | area of install | Hight(m) |

| QG50 | 50 | 7 | 16 | 10 |

| QG100 | 100 | 13 | 26 | 11 |

| QG200 | 200 | 21 | 35 | 12 |

| QG250 | 250 | 24 | 51 | 13.5 |

| QG500 | 500 | 43 | 78 | 15 |

| QG1000 | 1000 | 100 | 105 | 20 |

| QG1500 | 1500 | 150 | 200 | 23 |

GFF系列

model | Evaporation capacitykg/h | powerkw | Area coveredm2 | heightm |

| GFF-300 | 25 | 7.5 | 4x4 | 5.5 |

| GFF-400 | 50 | 11 | 4x6.5 | 6.5 |

| GFF-500 | 75 | 13 | 4x7 | 7.5 |

| GFF-600 | 100 | 17 | 5x6 | 8.0 |

| GFF-800 | 200 | 29 | 5x9 | 9.0 |

FG series

model | moisture to be evaporated(kg/h) | equipped power(kW) | area of install(m2) | High(m) |

| FG0.25 | 113 | 11 | 3.5x3.5 | >80 |

| FG0.5 | 225 | 18.5 | 7x5 | >80 |

| FG0.9 | 450 | 30 | 7x6.5 | >80 |

| FG1.5 | 675 | 55 | 8x7 | >80 |

| FG2.0 | 900 | 75 | 11x7 | >80 |

| FG2.5 | 1125 | 90 | 12x8 | >80 |

| FG3.5 | 1500 | 110 | 14x10 | >80 |

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

Due to the high air velocity, the particles disperse well in the gas phase. The total surface area of particles can be regarded as the effective drying area. Greatly increased, high-speed flow of air flow makes the gasification surface continuously updated. Therefore, the heat and mass transfer process of drying is strong. The evaporation capacity is large, from 50kgh2o / h to 2000kgh2o / h.

Short drying time. The contact time of gas-solid phase is very short, and the drying time is usually completed in a few seconds. The thermal denaturation of materials is generally a function of temperature and time. Therefore, for materials with thermal sensitivity or low melting point, it will not cause overheating decomposition and affect the quality.

High thermal efficiency. The gas-solid two-phase parallel flow operation is adopted in the air flow drying. Moreover, in the surface gasification stage, the material temperature generally does not exceed 60-65 ℃. In the rising stage of the material temperature at the end of the drying stage, the gas temperature has been greatly reduced, and the product temperature does not exceed 70-90 ℃. Therefore, high temperature gas can be used for drying, with high heat utilization rate.

Large processing capacity, large evaporation capacity, simple equipment, small land occupation and low investment. At the same time, the unit processes of drying, crushing, screening and conveying can be operated jointly, which not only simplifies the process, but also makes the operation easy to be controlled automatically.

It has a wide range of applications, and can be applied to all kinds of powder and granular materials.

A variety of heat sources can be selected, including steam heating, heat-transfer oil heating or coal-fired, oil fired, gas-fired hot blast furnace and other heat source equipment.

There are a variety of structural forms for selection, customers can choose according to the material property requirements: QG general type, GFF intensified belt pulverizer type, FG tail gas cycle energy-saving type and other models with different functions.

Special dryer for guar gum

Many times upgrade, not only reduce the height of the dryer to a large extent, but also design a number of flushing ports on the dryer. The successful design of the special dryer for guar gum saves a lot of energy for the country, improves the economic benefits of the enterprise, and makes a certain contribution to the progress and development of guar gum in China. Guar gum enters into the dryer at the same time through the conveyor and the heated natural air. The two are fully mixed. Because of the large heat and mass exchange area, the purpose of evaporation and drying can be achieved in a very short time. The dried product is discharged from the cyclone separator, and a small part of the fly powder is recycled by the bag filter.

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION

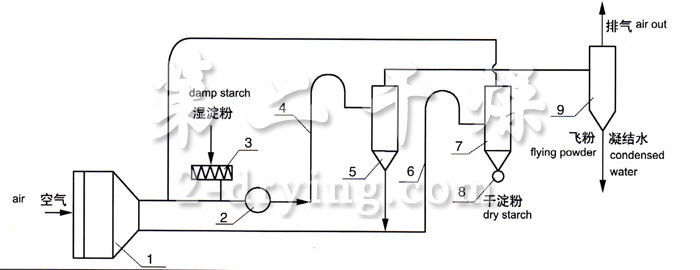

QG series

Basic air drying equipment, suitable for loose, small viscosity, finished products for particles and powder materials. The flow chart is negative pressure air drying. Users can choose positive pressure drying method according to product characteristics.

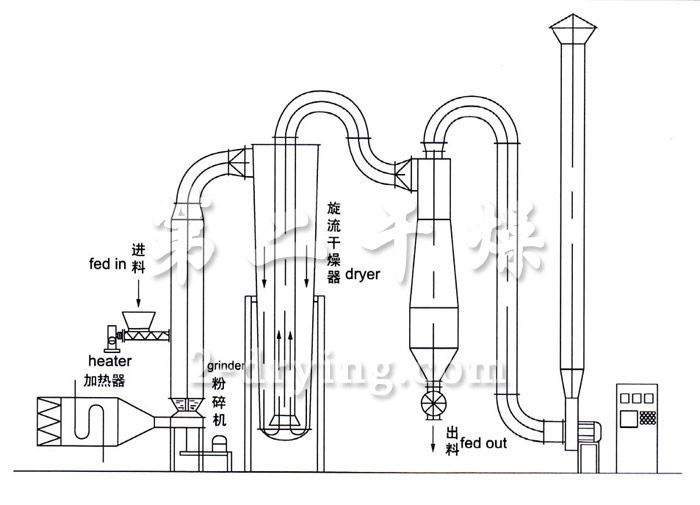

GFF 系列

设备带强化粉碎装置,具有产品终水份低、设备占地面积小、高度低等特点,适用于滤饼、膏状、带有一定粘性、要求成品为粉末状的产品。

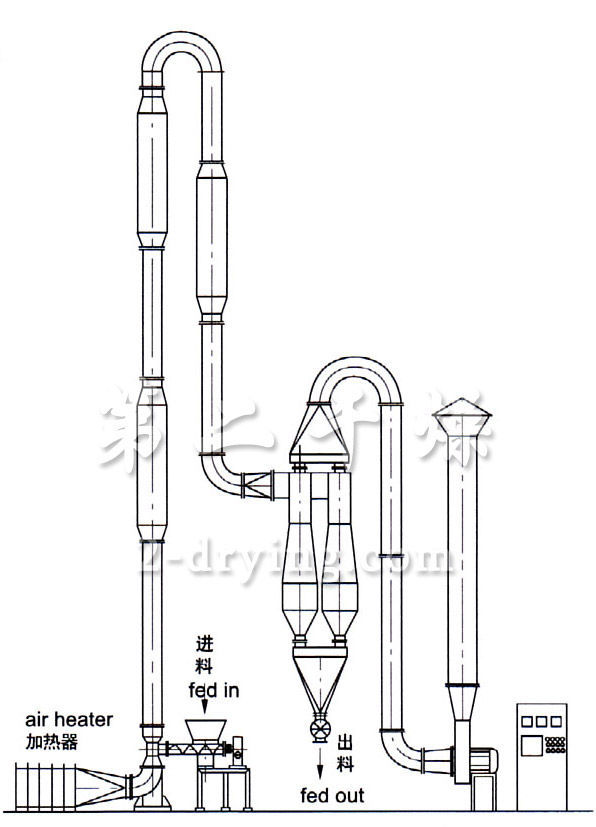

FG 系列

具有尾气循环使用比一般气流干燥机节能30% 的优点,适用于无粘性、松散状物料,成品为颗粒及粉末。