ZRL series direct fired coal-fired hot blast furnace

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

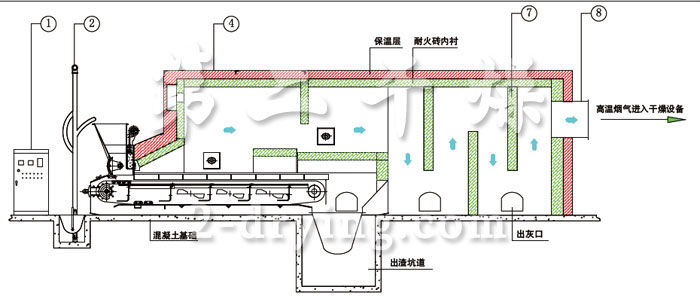

ZRL series combustion furnace uses coal as fuel to form high temperature flue gas. The flue gas purified by sedimentation is directly used in dry direct fired hot blast furnace. It can be used in the drying system with high air inlet temperature and low requirement for hot air cleanliness.

When the combustion furnace is working, coal is added to the coal hopper at one end of the grate by the coal loader, and the coal seam with adjustable height according to the calorific value is uniformly sent to the combustion chamber by the chain grate. Under the action of the combustion fan, the high temperature flue gas generated by combustion is sent out to the drying equipment after settling from the outlet at the other side of the combustion furnace, and the temperature of the hot air can be adjusted according to the process needs. The burnt out coal slag falls into the slag extractor from the end of the chain grate for discharge.

The combustion furnace adopts the form of horizontal chain grate, which is equipped with high temperature combustion chamber and settling chamber to fully burn the gas and carbon content in the coal, improve the combustion effect, control the dust content and reduce wear.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| model | Heat source | Heating temperature | Coal consumption | thermal efficiency | Installed capacity | Outline size | Total weight | |

| 104kcal/h | 104kj/h | oC | kg/h | % | kw | (L×D×H) m | T | |

| ZRL-60 | 60 | 251 | 60-800 | 124 | ≥88 | 3.5 | 5.0×1.3×3.2 | 8 |

| ZRL-120 | 120 | 505 | 60-800 | 248 | ≥88 | 5.6 | 5.5×1.6×3.4 | 14 |

| ZRL-180 | 180 | 753 | 60-800 | 372 | ≥88 | 6.7 | 6.0×1.8×3.4 | 18 |

| ZRL-240 | 240 | 1005 | 60-800 | 496 | ≥88 | 10.3 | 6.5×2.2×3.4 | 22 |

| ZRL-360 | 360 | 1507 | 60-800 | 744 | ≥88 | 11 | 6.8×2.4×3.4 | 28 |

| ZRL-480 | 480 | 2009 | 60-800 | 992 | ≥88 | 12.8 | 7.0×2.6×3.6 | 32 |

| ZRL-600 | 600 | 2511 | 60-800 | 1240 | ≥88 | 17 | 7.5×2.7×3.6 | 39 |

| ZRL-960 | 960 | 4018 | 60-800 | 1983 | ≥88 | 19.5 | 8.5×3.1×3.6 | 46 |

| ZRL-1200 | 1200 | 5023 | 60-800 | 2480 | ≥88 | 25.5 | 8.8×3.3×3.6 | 61 |

Note: 1. The data in the table is for reference only. Please consult our company for details. 2. Medium quality bituminous coal is used, with a calorific value of 5500kcal / kg.

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

The combustion furnace is a general-purpose hot air heating device, which is suitable for drying various kinds of indirect food materials such as ore, sludge, leather protein, pharmaceutical residue, casting sand, ceramic body, wood, cement, etc.

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

1. The output temperature can reach 800oC.

2. Small investment, low operation cost, small floor area and long service life.

3. High thermal efficiency, convenient temperature regulation, stable heating, safe and reliable.

4. High degree of mechanization, convenient operation, easy ignition, fast temperature rise and good sealing performance.

5. It has strong adaptability to coal types, and can use a variety of coal with a calorific value of more than 4000kcal / kg.

6. It can be used for combustion of various fuels, such as biomass sawdust particles, etc.

7. It has strong adaptability to dryers and can be used with various dryers.

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION