SZG series double cone rotary vacuum dryer

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

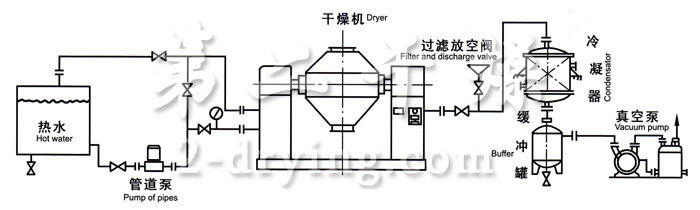

Double cone rotary vacuum dryer is a new type of dryer which integrates mixing and drying. The condenser and vacuum pump are matched with the dryer to form a vacuum drying device. This machine has advanced design, simple internal structure, easy cleaning, all materials can be discharged, easy operation, reducing labor intensity and improving working environment. At the same time, because the material rotates when the container rotates, but there is no material on the wall of the container, the heat transfer coefficient is high and the drying rate is large, which not only saves energy, but also makes the material dry evenly and sufficiently with good quality. It can be widely used in the drying of pharmaceutical, chemical, food, dyestuff and other industries. Meet the requirements of GMP.

|  |

P

RINCIPLE

PRINCIPLE

Reliable supplier of drying equipment users

RINCIPLE PRINCIPLE

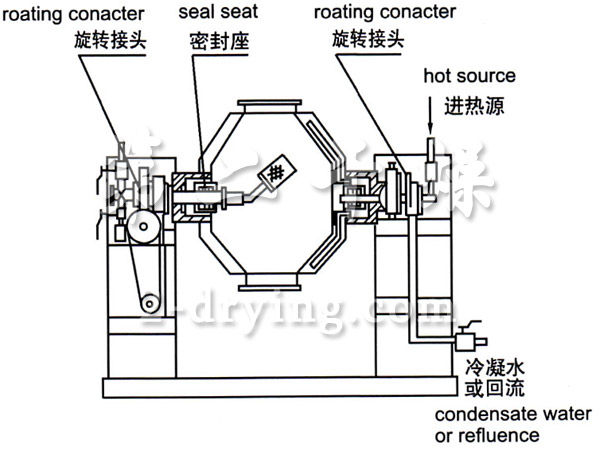

SZG double cone rotary vacuum dryer is a double cone rotary tank. In the vacuum state of the tank, steam or hot water is introduced into the jacket for heating, and the heat contacts the wet material through the inner wall of the tank. The water vapor evaporated after the wet material absorbs heat is pumped out through the vacuum exhaust pipe through the vacuum pump. Because the tank is in a vacuum state, and the rotation of the tank makes the material department constantly up and down, inside and outside, so it speeds up the drying speed of materials, improves the drying efficiency, and achieves the purpose of even drying.

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

| project | type | ||||||||||

| name | unit | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4500 |

| Total volume | L | 100 | 200 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4500 |

| Working volume | L | 50 | 100 | 175 | 250 | 375 | 500 | 750 | 1000 | 1500 | 2250 |

| Heating area | m2 | 1.16 | 1.5 | 2 | 2.63 | 3.5 | 4.61 | 5.58 | 7.5 | 9.6 | 13.8 |

| speed | r/min | 6 | 4 | 6 | |||||||

| power | kW | 0.75 | 1.1 | 1.5 | 1.5 | 2 | 3 | 3 | 4 | 5.5 | 7.5 |

| Height of bogie | mm | 1810 | 1910 | 2090 | 2195 | 2500 | 2665 | 2915 | 3055 | 3330 | 4210 |

| Design pressure in tank | Mpa | -0.09~0.096 | |||||||||

| Mezzanine design pressure | Mpa | 0.3 | |||||||||

A

PPLICATION

APPLICATION

Reliable supplier of drying equipment users

PPLICATION APPLICATION

This machine is suitable for vacuum drying and mixing of powder and granular materials in medicine, food, chemical and other industries, especially for materials with the following requirements:

Heat sensitive materials that cannot withstand high temperature:

Materials easy to oxidize and dangerous;

Materials requiring recovery of solvents and toxic gases:

Materials with very low residual volatile content are required;

It is required to mix sufficient and even materials;

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

When the oil is heated, it can dry biochemical products and mineral raw materials with automatic constant temperature control. The temperature can be between 20-160 ℃ and within ± 2 ℃.

High thermal efficiency, more than 2 times higher than ordinary oven.

Indirect heating, materials will not be contaminated, in line with the "GMP" requirements. The equipment is easy to maintain and clean.

P

rocess

PROCESS

Reliable supplier of drying equipment users

rocess PROCESS

C

ONSTRUCTION

CONSTRUCTION

Reliable supplier of drying equipment users

ONSTRUCTION CONSTRUCTION