Pharmaceutical GMP oven, pharmaceutical oven, oven

S

UMMARIZE

SUMMARY

Reliable supplier of drying equipment users

UMMARIZE SUMMARY

P

ARAMETER

PARAMETER

Reliable supplier of drying equipment users

ARAMETER PARAMETER

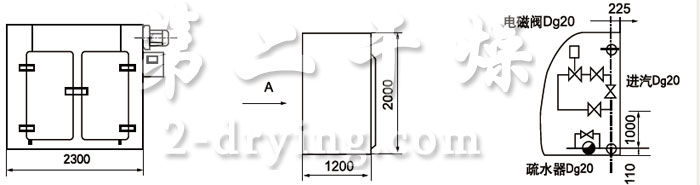

Technical parameters/ Model specification | Amount of each drying (kg) | Fan power(kw) | Steam consumption(kg/h) | Bake car (vehicle) | Baking tray (only) | W×D×H (mm) | Temperature difference between top and bottom(℃ ) |

| GMP-O | 35 | 0.45 | 8 | / | 16 | 1130×1100 ×1750 | ±2 |

| GMP-I | 120 | 0.45 | 18 | 2 | 48 | 2300×1200 ×2000 | ±2 |

| GMP-II | 240 | 0.9 | 36 | 4 | 96 | 2300×2200 ×2000 | ±2 |

| GMP-III | 360 | 1.35 | 54 | 6 | 144 | 2300×3220 ×2000 | ±2 |

| GMP-IV | 480 | 1.8 | 72 | 8 | 192 | 4460×2200 ×2290 | ±2 |

F

EATURE

FEATURE

Reliable supplier of drying equipment users

EATURE FEATURE

There are four heating methods: steam, electricity, heat-transfer oil and electricity plus steam.

Service temperature: steam heating 50 ~ 140 ℃, high temperature 150 ℃, electric heating 50 ~ 350 ℃, heat conduction 150 ~ 250 ℃

The temperature is controlled automatically and recorded by a recorder.

The inner wall of the box is fully welded, and each transition point adopts arc transition without dead angle.

The sealing performance of the whole machine is good. The unique sealing device of guide rail ensures the sealing performance of the whole machine.

The air inlet is equipped with high efficiency air filter, and the moisture outlet is equipped with medium efficiency air filter.

Double door oven with double doors realizes mechanical interlocking;

All parts in the oven can be disassembled and installed quickly to facilitate cleaning.

The control system is equipped with text display and touch screen for selection;

The whole machine meets the requirements of GMP.